Mastering HART Communication – A Must For instrumentation ProfessionalsÂ

Mastering HART Communication – A Must For instrumentation ProfessionalsÂ

Jul 24, 2025

Mastering HART communication is no longer optional for instrumentation professionals working in modern process industries. It’s a practical necessity for those seeking to remain relevant and effective in today’s hybrid analogue-digital environments. As part of any robust  instrumentation and control training, understanding HART plays a vital role in ensuring performance, safety, and career growth.Â

With the right tools, hands-on training, and an understanding of how HART fits into larger control systems, technicians and engineers can dramatically improve plant performance, safety, and reliability—while positioning themselves as leaders in  industrial automation.Â

In the rapidly evolving landscape of  process control training in Australia, the ability to communicate effectively with field instruments is essential. One technology that continues to play a vital role in bridging the gap between analogue and digital systems is HART (Highway Addressable Remote Transducer). HART protocol is not just a technical skill—it’s a strategic asset for instrumentation technicians and engineers working in smart process environments.Â

What is HART Communication?

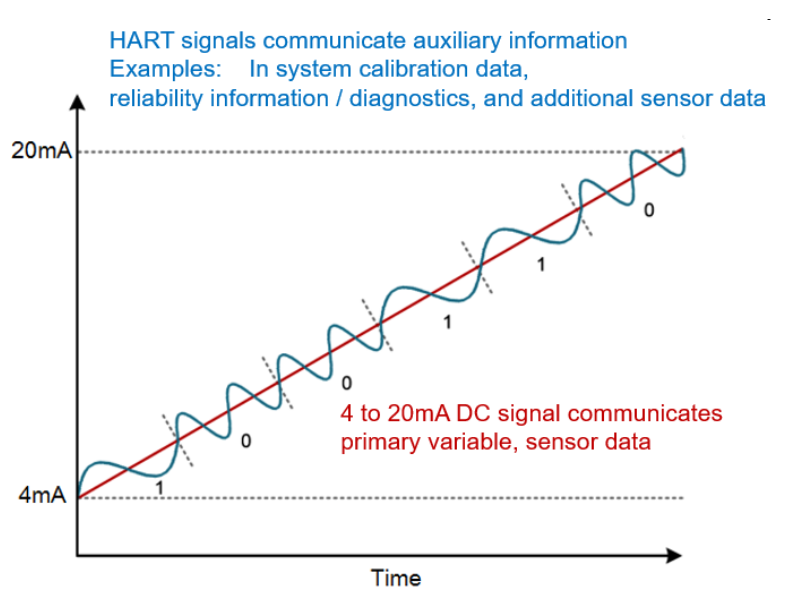

HART is a hybrid communication protocol that allows digital data to be superimposed on the traditional 4–20 mA analogue signal. Introduced in the late 1980s, HART enables two-way field communication between smart field devices and control or monitoring systems, sharing the pair of wires used by analogue-only host systems.

Figure: HART System

The HART Protocol provides two simultaneous communication channels: the 4-20 mA analog signal and a digital signal. The 4-20 mA signal communicates the primary measured value using the current loop—still the fastest and most reliable industry standard. Additional device information is communicated using a digital signal that is superimposed on the analog signal.

The digital signal contains information from the device including status, diagnostics, additional measured or calculated values, and more. Together, the two channels provide a low-cost and robust communication solution that is easy to implement, configure, and troubleshoot.

Common Applications of HART in the Field

- Loop testing and calibration of transmittersÂ

- Remote configuration of devices from a control roomÂ

- Field asset management using handheld communicators or HART modemsÂ

- Integration with DCS and SCADA systems for enhanced visibilityÂ

- Troubleshooting sensor errors or signal inconsistenciesÂ

Tools You Need to Work with HART

To effectively use and troubleshoot HART-enabled instruments, technicians must be proficient with:

- HART Communicators (e.g., Emerson 475, AMS Trex, or ProComSol modems)Â

- Device Descriptor (DD) libraries for reading specific instrument parametersÂ

- PC-based HART configuration software for diagnostics and reportingÂ

- Multimeters with HART compatibility for loop testing and signal verificationÂ

Competency with these tools enables faster calibration, fewer field visits, and accurate interpretation of device behaviour—key components of effective  PLC and instrumentation training.Â

Key Skills for Mastering HART

To become proficient with HART, technicians should develop capabilities in five key areas:

- Protocol UnderstandingÂ

- Grasp how digital FSK signals operate over analogue loopsÂ

- Recognise limitations (e.g., polling speed, loop resistance)Â

- Device ConfigurationÂ

- Configure ranges, setpoints, damping, and alarmsÂ

- Save and restore device settings and calibrationsÂ

- Diagnostics & TroubleshootingÂ

- Interpret HART status codes and fault flagsÂ

- Trace faults across signal paths, sensors, or wiringÂ

- Integration with Control SystemsÂ

- Understand how HART data is integrated into DCS, PLC, and SCADA systemsÂ

- Learn how to use multiplexers or HART-enabled I/O cards for remote accessÂ

- Looking Ahead: HART and IIoTÂ

- Learn how HART-IP supports Ethernet integrationÂ

- Enable real-time diagnostics, trending, and cybersecurity within IIoT systemsÂ

- Use HART data to fuel predictive maintenance and smart decision-makingÂ

Training and Certification Opportunities

If you’re serious about mastering HART, consider enrolling in a course that includes:

- Smart Instrumentation FundamentalsÂ

- HART Protocol Hands-On TrainingÂ

- Device Commissioning and Loop TestingÂ

- Advanced Field CommunicationÂ

These topics are typically covered in comprehensive programs such as the  Certificate IV in Instrumentation and Control, which forms the foundation for those entering or upskilling in the field of  process control training in Australia.Â

Such certification-based pathways, including the  UEE42220  qualification, are designed to provide real-world scenarios, simulator-based learning, and hands-on experience with smart instruments—building both confidence and technical capability. A well-rounded  industrial automation course  will always integrate HART protocol as part of its instrumentation focus.Â

Whether you’re a student, technician, or working professional, getting the right  instrumentation and control training  is key to staying competitive. PMV Training’s nationally accredited courses such as the  Certificate IV in Instrumentation and Control offer industry-aligned curriculum, hands-on labs, and practical knowledge to help you grow.Â

👉 For expert-led  PLC and instrumentation training, including real-world HART protocol workshops, get in touch with PMV Training  today.Â

Recent Post

Jul 16, 2025

Jun 26, 2025